Textra & Textra Sport

Die neueste Innovation von Thermopatch ist Textra. Ein Transfer basierend auf jahrelanger Erfahrung in der Patchtechnologie verbunden mit den neuesten Digitaldrucktechniken.

Ein intelligenter Produktionsprozess mit modernen Tinten verleiht Textra eine hohe Qualität und Aussehen dank seiner brillianten Farben. Ein zusätzlicher Vorteil ist eine kurze Lieferzeit und ein interessanter Preis.

Textra Sport

Textra Sport hat fast die gleichen Eigenschaften wie Textra. Großer Vorteil dieser Transfers ist jedoch die Dehnbarkeit. Mit hoher Druckqualität und Langlebigkeit ist es ein ideales Produkt für geschmeidige und dehnbare Stoffe wie Sportbekleidung. Textra Sport ist erhältlich in jeder Größe und Form und sehr intensiven Farben.

Aufgrund einer niedrigeren Temperatur während der Versiegelung und ein sogenannter Blocker, wird die Sublimation von Farbe in Kleidung oder irgendeinem anderen Textil verhindert.

Sowohl Textra als auch Textra Sport sind nicht in PMS-Farben erhältlich.

Textra and Textra Sport Transfer

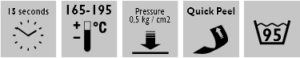

| Textra |  |

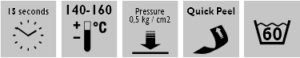

| Textra Sport |  |

For more detailed press instructions for Textra transfers on various fabrics, click here.

Description

Textra and Textra Sport are heat seal transfers with a broad range of applications. The transfer consists of a carrier foil onto which an image which has been printed with an additional glue layer for the adhesion to textile. Textra type transfers are compliant to Oekotex100, class I, under certificate number 1110043 Centexbel.

Application

- Textra is suited for mild industrial washing processes, for coloured workwear

- Textra Sport transfers are ideal for sportswear and promotional articles such as polo-, sweat– and T-shirts, with enhanced stretching properties. Blocking agents can be added for improved resistance to dye migration from sublimated and dispersed dyed polyester textiles

Properties

Wash resistant up to 75°C coloured workwear washing for Textra and 60 °C domestic washing for Textra Sport and up to 40 °C domestic washing for Textra Sport added with an extra blocking layer. These transfers are suitable for all textiles which allow the thermoplastic adhesive to penetrate and bind itself to it and which are resistant to its application temperatures.

Limitations of use

None, when care label instructions of the underlying textile are followed.

Physical properties

Various, depending on size.

Before heat sealing

Ensure that the to be marked textile is free of lint, dust, dirt. No seams, zippers, buttons etc. should be near the location where the heat sealing will be performed.

Remark: Good bonding can be prevented in pre-conditioned fabrics with a dirt or water repellent coating such as fluorocarbon finishes or flame retardant finishes.

Heat seal instructions

Make sure that the sealing plate of the machine is clean and undamaged.

| Type | Temperature °C | Time seconds | Pressure kg/cm2* | Washing |

| Textra | 165-185 | 15 | 0.5 | 95 °C |

| Textra Sport | 140-160 | 15 | 0.5 | 60 °C |

Textra transfers are quick peel; remove the garment from the press before removing the transfer foil to allow the adhesive to set for a moment. Remove the foil when the transfer is still warm to the touch.

* For an optimal heat sealing result we advise to set the pressure on any large platen pneumatic heat seal press to 3-5 bar on the pressure regulator of the machine, when using the standard issued under platen. When using smaller underplates, decrease pressure to avoid damage to the transfers.

Handling and storage

Keep away from oxidising agents, from strongly alkaline and strongly acidic materials.

Store out of direct sunlight, in a cool and dry place.

Shelflife: 1 year when stored in their original packing, out of direct sunlight, in a cool and dry place.

Precautions

No specific safety measures are required when working with this product. We advise to ventilate well at heat sealing activities, since vapours may occur from any textiles being processed.

Exposure controls / personal protection

Ensure a sufficient amount of fresh air when there is a risk of release of fumes, for instance when heating the product.

Personal protection equipment:

- For the hands: None

- For the eyes: None

- For the skin: None

- For breathing: None

Hazards identification

The product has not been subjected to classification following the European legislation. Special hazards designation for humans and environment: Not applicable.

Disclaimer

This information is based on the current state of our knowledge. It is however, no guarantee of product features and no contractual relationship.

Recommended restrictions apply

This product should not be used for purposes other than specified.

Scroll down for Textra Sport and Textra Sport with blocker.

| Textra (high temperature, quick peel, possible with migration-blocking layer, up to 95 °C for colored laundry) | |||

| Type of fabric | Temp. °C | Pressing time in sec. | Pressure in Bar Low/Medium/High |

| Fleece, 100% Polyester | 160 | 15 | 4-5 (Medium/High) |

| Polyurethane or PVC-coated polyester (rainwear), cover with baking paper | 135-150 | 15 | 2-3 (Low) |

| Knitted fabrics, 100% polyester, viscose, acrylic (sportswear, light workwear) | Preheat 160 |

7-10 15 |

4-5 (Medium/High) |

| Knitted fabrics, 100% wool, cotton (sportswear, light workwear) | 165-175 Repress |

15 7-10 |

4-5 (Medium/High) |

| Knitted fabrics, cotton or polyester with elastane 98%/2% | Preheat 160 |

10 15 |

2-3 (Low) |

| Cotton or polyester cotton 65%/35% | 180-195 | 15 | 4-5 (Medium/High) |

| Flame-retardant cotton or polyester cotton (FR treated, Proban®) | Preheat 180-195 |

7-10 15-12 |

4-5 (Medium/High) |

| Cotton/polyamide 55%/45% | 165 | 15 | 4-5 (Medium/High) |

| Cotton/polyester 65%/35% or 60%/40%

(with DWR finish)* |

165 | 15 | 4-5 (Medium/High) |

| Aramid/Viscose 50%/50% | 170 | 15 | 4-5 (Medium/High) |

| Linen, 100% | 165 | 15 | 4-5 (Medium/High) |

| Aramid (Nomex III), 100% | 165 | 15 | 4-5 (Medium/High) |

| Polyamide (Nylon), 100% (with DWR finish)* | Preheat 165 |

7-10 15 |

4-5 (Medium/High) |

| Polyester 100% (with DWR finish)* | Preheat 165 |

7-10 15 |

4-5 (Medium/High) |

| Polyester Cleanroom material anti-static 99%/1% | Preheat 165 -175 |

7-10 18-15 |

4-5 (Medium/High) |

| Textra Sport (low to medium temperature, digital transfers, quick peel, possible with migration-blocking layer, up to 60°C for colored laundry) | |||

| Type of fabric | Temp. °C | Pressing time in sec. | Pressure in Bar Low/Medium/High |

| Fleece, 100% Polyester | 150 | 12 | 4-5 (Medium/High) |

| Polyurethane or PVC-coated polyester (rainwear), cover with baking paper | 135-150 | 15 | 2-3 (Low) |

| Knitted fabrics, 100% polyester, viscose, acrylic (sportswear, light workwear) | 150 Repress |

15 7-10 |

4-5 (Medium/High) |

| Knitted fabrics, 100% wool, cotton (sportswear, light workwear) | 155-165 Repress |

15 7-10 |

4-5 (Medium/High) |

| Knitted fabrics, cotton or polyester with elastane 98%/2% | Preheat 145 |

10 15-18 |

2-3 (Low) |

| Cotton or polyester cotton 65%/35% | 160 | 15 | 4-5 (Medium/High) |

| Flame-retardant cotton or polyester cotton (FR treated, Proban®) | Preheat 155 |

7-10 15 |

4-5 (Medium/High) |

| Cotton/polyamide 55%/45% | 155 | 15 | 4-5 (Medium/High) |

| Cotton/polyester 65%/35% or 60%/40%

(with DWR finish)* |

155 | 15 | 4-5 (Medium/High) |

| Aramid/Viscose 50%/50% | 160 | 15 | 4-5 (Medium/High) |

| Linen, 100% | 165 | 15 | 4-5 (Medium/High) |

| Aramid (Nomex III), 100% | 160 | 15 | 4-5 (Medium/High) |

| Polyamide (Nylon), 100% (with DWR finish)* | 155 | 15 | 4-5 (Medium/High) |

| Polyester 100% (with DWR finish)* | 155 | 15 | 4-5 (Medium/High) |

| Polyester Cleanroom material anti-static 99%/1% | Preheat 165 |

7-10 18 |

4-5 (Medium/High) |

| Textra Sport with blocker for anti-sublimation and anti-migration (up to 40 °C) | |||

| Type of fabric | Temp. °C | Pressing time in sec. | Pressure in Bar Low/Medium/High |

| Softshell | 145-155 | 15 | 3 (Low) |

| Sublimated polyester (100%) | 145 | 15 | 4 (Medium/High) |

| Fleece, 100% Polyester | 150 | 12 | 4-5 (Medium/High) |

| Polyurethane or PVC-coated polyester (rainwear), cover with baking paper | 135-150 | 15 | 2-3 (Low) |

| Knitted fabrics, 100% polyester, viscose, acrylic (sportswear, light workwear) | 150 Repress |

15 7-10 |

4-5 (Medium/High) |

| Knitted fabrics, 100% wool, cotton (sportswear, light workwear) | 155-165 Repress |

15 7-10 |

4-5 (Medium/High) |

| Knitted fabrics, cotton or polyester with elastane 98%/2% | Preheat 145 |

10 15-18 |

2-3 (Low) |

| Cotton or polyester cotton 65%/35% | 160 | 15 | 4-5 (Medium/High) |

| Flame-retardant cotton or polyester cotton (FR treated, Proban®) | Preheat 155 |

7-10 15 |

4-5 (Medium/High) |

| Cotton/polyamide 55%/45% | 155 | 15 | 4-5 (Medium/High) |

| Cotton/polyester 65%/35% or 60%/40%

(with DWR finish)* |

155 | 15 | 4-5 (Medium/High) |

| Aramid/Viscose 50%/50% | 160 | 15 | 4-5 (Medium/High) |

| Linen, 100% | 165 | 15 | 4-5 (Medium/High) |

| Aramid (Nomex III), 100% | 160 | 15 | 4-5 (Medium/High) |

| Polyamide (Nylon), 100% (with DWR finish)* | 155 | 15 | 4-5 (Medium/High) |

| Polyester 100% (with DWR finish)* | 155 | 15 | 4-5 (Medium/High) |

| Polyester Cleanroom material anti-static 99%/1% | Preheat 165 |

7-10 18 |

4-5 (Medium/High) |

*DWR finish: Durable Water Repellent finish, meaning a water (dirt, oil) repellent coating on textiles based on silicone, nanotechnology, wax, and fluorocarbon.

FR: Flame Retardant

Disclaimer

No rights can be derived from the instructions or data provided online. The information is intended for general guidance only and is subject to change without notice. We do not guarantee the accuracy, completeness, or reliability of the information provided. Users are advised to verify any information before acting on it. We accept no liability for any damage incurred because of relying on this information.

Besondere Eigenschaften

- High-Tech und bunt

- Scharfe Details

- Fotografische Bilder und Farbverläufe

- Anwendbar für verschiedene Textilien