DigiPro

Unlock the potential of DigiPro! Craft custom high-quality textile emblems in-house. Fast, cost-efficient, and on-demand. DigiPro is the ultimate solution for time savings and low production costs, without compromising on quality.

I am interested in this product

Why Choose DigiPro?

Industrial laundries, textile manufacturers, and corporate clothing producers rely on a vast stock of textile emblems. They benefit from short delivery times, low transportation costs, and minimal investments. DigiPro provides a solution on all fronts. With DigiPro, you can internally produce your textile emblems, ensuring your ability to respond flexibly to market demand. Thanks to DigiPro, you have access to an advanced UV inkjet printer with a cutting plotter that is easy to operate. When combined with specially designed textile rolls with thermoplastic adhesive by Thermopatch, you can effortlessly create emblems in any shape and color, in the highest quality. DigiPro maximizes your business’s flexibility.

How does it work?

With DigiPro’s in-house printing options, you can get started right away. All you need is a suitable space at your location. The essential components of the DigiPro concept include:

- A professional inkjet printer with an integrated cutting plotter

- Textile rolls with a thermoplastic adhesive layer

- Design support

Using the versatile printer with a cutting plotter and accompanying software, you can create emblems of any size, shape, and color quickly. It’s even possible to print photographic images. Afterward, you instruct the printer via a computer or laptop to precisely cut the prints, resulting in immediately usable emblems. And just as important, all emblems you produce are industrially washable.

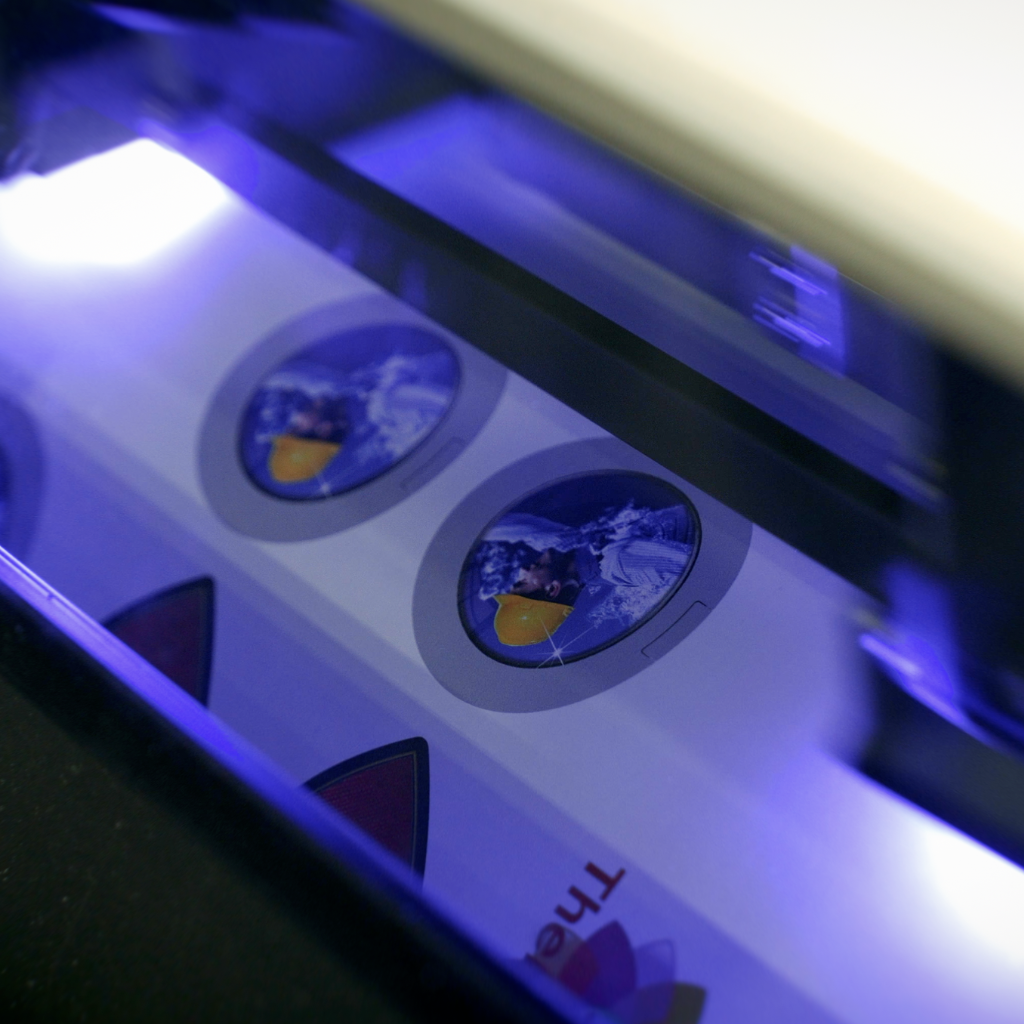

DigiPro is exclusively integrated with the Roland MG-640, the ultimate choice for top-quality emblem printing and cutting. LED lights in the printer ensure that UV inks dry instantly without generating heat, allowing seamless printing on thermoplastic adhesive-backed textiles. The Roland MG-640 also serves as a cutting plotter, enabling you to create precise contours.

Textile rolls for DigiPro

With DigiPro, we aim to provide ease of use and top quality for our customers. That’s why we offer specially developed textile rolls for DigiPro with a thermoplastic adhesive layer, ensuring perfect results. The choices include Digiline, Digiline Pro, and Digiline FR as base materials, ideal for further processing on heat seal presses. The rolls are 135 centimeters wide and come in rolls of up to 20 meters in length.

Software and Training

The Roland MG-640 printer with an integrated cutting plotter and related software are supplied by Thermopatch. We are also responsible for installation, maintenance, and training.

Thermopatch’s Design Studio services

Before you can print an emblem with the Roland MG-640, a design file is required, including the necessary colors and cutting lines. You can make use of Thermopatch’s Design Studio services through the online portal. Simply place your order, and our team will ensure that a ready-to-use file is available to you within 24 hours.

| Specifications Roland MG-640 | ||

| Print method | Piëzo ink-jet method | |

| Media | Width | 210 to 1625 mm (8.3 to 64 inches) |

| Thickness | Max 1.0 mm (39.3 mil) with liner for printing Max 0.4 mm (15.7 mil) with liner and 0.22 mm (8.6 mil) without liner for cutting |

|

| Roll outer diameter | Max 210 mm (8.2 in.) | |

| Roll weight | Max. 40 kg (88 lb) | |

| Core diameter | 76,2 mm (3 in.) or 50,8 mm (2 in.) | |

| Print/cut width1 | Max. 1600 mm (62,9 in.) | |

| Ink | Type | ECO-UV (EUV5) 220 ml cartridge (white)

ECO-UV (EUV5) 500 ml cartridge (cyan, magenta, yellow, black, red, orange, gloss, primer) |

| Color configurations | Eight colors (cyan, magenta, yellow, black, red, orange, white, gloss) Seven colors (cyan, magenta, yellow, black, red, orange, white) Seven colors (cyan, magenta, yellow, black, red, orange, white) and primer Seven colors (cyan, magenta, yellow, black, red, white, gloss) and primer Six colors (cyan, magenta, yellow, black, white, gloss) and primer Six colors (cyan, magenta, yellow, black, white, gloss) Four colors (cyan, magenta, yellow, black) |

|

| Ink drying system | Built-in UV-LED lamp | |

| Print resolution (dots per inch) | Max. 1440 dpi | |

| Cutting speed | 10 to 300 mm/s (0,39 tot 11,8 inches/s) | |

| Blade force2 | 30 to 500 gf | |

| Blade | Type | Roland CAMM-1 series blade |

| Offset | 0 to 1.500 mm (0 tot 59 mil) | |

| Software resolution (when cutting) | 0,025 mm/step (0,98 mil/step) | |

| Connectivity | Ethernet (100BASE-TX/1000BASE-T, automatic switching) | |

| Power saving | Automatic sleep mode | |

| Power supply | 100-240 V AC 50/60 Hz 2,8 A | |

| Power consumption | During operation | Approx. 250 W |

| Sleep mode | 40 W | |

| Acoustic noise level | During operation | 63 dB (A) or less |

| During stand-by | 53 dB (A) or less | |

| Dimensions (with stand) | 2819 (B) x 781 (D) x 1316 (H) mm (111 [B] x 31 [D] x 52 [H] in.) | |

| Weight (with stand) | 163 kg (360 lb.) | |

| Shipping weight and dimensions | L 295 x W86 x H 82 cm – 226kg | |

| Commodity code | 8443321000 – CoO: TH | |

| Environment | During operation3 | Temperature: 15 to 32°C (59 to 89.6°F), humidity: 20 to 80% RH (no condensation) |

| When off | Temperature: 5 to 40°C (41 to 104°F), humidity: 20 to 80% relative humidity (no condensation) | |

| The specifications, design, and dimensions mentioned are subject to change without prior notice. 11Print or cut length depends on program limitations. 2500 gf is the maximum immediate blade force. Blade force should be set based on details such as media thickness. 3Operating environment (for use in a business environment within this range.) |

||

Highlights

- create textile emblems on demand

- low production costs

- time saving

- flexibility