Mending

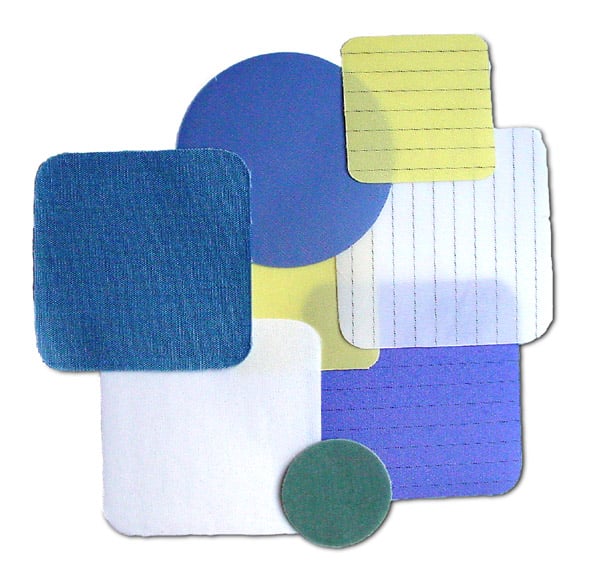

Thermopatch has a wide variety of heat-seal mending materials, Shirt weight, Pant weight, Flame Retardant, Glove mending, Spun Poly, Barrier cloth, Sheeting and other miscellaneous materials all in various colors.

Click on the ‘documentation tab’ to find our mending chart. All of these materials are available in pre-cut rounds, squares or on rolls. If you do not see a color or material you are looking for please see our custom lamination page or if it is a small special quantity you are looking to repair, see our Thermoply page and make your own patches.

Why use Thermopatch Mending patches?

It’s all in the adhesive. The materials you know, we use the same ones that are manufactured in your garments.

Anytime we add a new material to our standard product chart, we test a wide variety of adhesives to see which gives the greatest bond strength and next which is economically better for you. Some materials have coated finishes that certain adhesives react to better than others.

Whether you are repairing a spun poly garment, navy pant or barrier fabric, we have the material and best adhesive for the job!

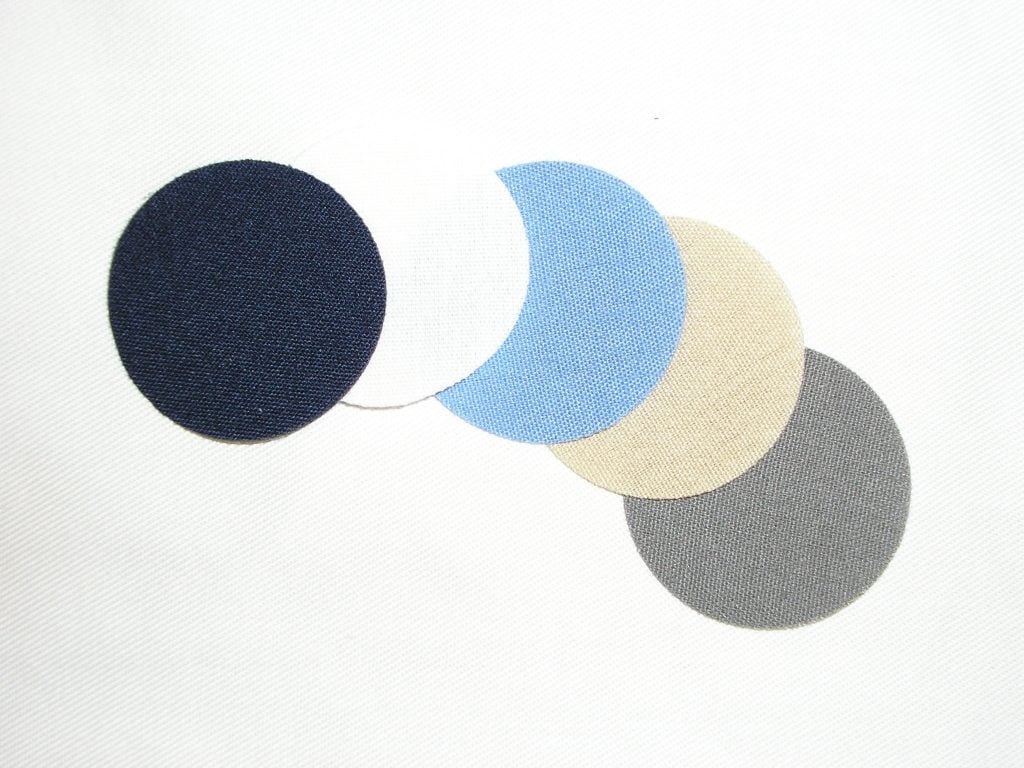

Color coding?

Try our ½” round patches. Simply select the color patch and place it next to the identification label while heat-sealing. Both heat-seal on at the same specifications so it makes color coding a breeze.

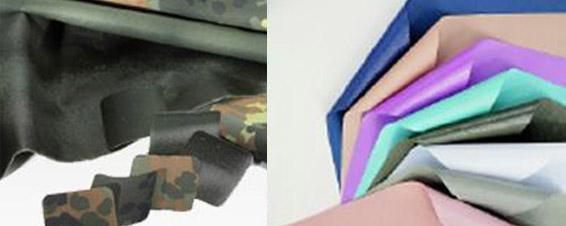

Glove Mending Patches

Industrial gloves are expensive and it pays off when they can be repaired. Especially the gloves that contain simulated leather and fire resistant material. For this reason we have a range of special patches in our program that has been developed for glove mending.

Finger repair

The damaged finger should be placed on the lower press platen of your heat seal machine with remaining fingers folded away from platen area. Place appropriate size patch on top of area to be mended and activate the press. When using a butterfly patch to mend both sizes of a finger, preheat finger and fold patch over fingertip. Heat-seal patch on one size of finger, turn glove over and repeat procedure.

Palm repair

Place palm on lower press platen with damaged area facing up. Stretch fingers to make glove as flat as possible. If necessary, close press for a few seconds to flatten palm. Then proceed as above.

Repairs between fingers

Repairs, particularly between the thumb and index finger, can be simplified by first spreading the fingers apart and preheating. Then proceed as above.

Why preheat?

Preheating flattens the area to be mended for easier positioning of the patch. It also heats the glove, so the patch becomes tacky when placed in contact with the heated glove and remains in place until the permanent repair is made. Proper preheating takes about 8 seconds.

Press time

Varying with type of glove the press time is 8 to 15 seconds. Please bear in mind that when repairing leather gloves, the time cycle should be limited to approximately 10 seconds to prevent shrinkage.